Skills - Foundry Casting

Foundry Casting

Foundry casting involves the pouring of molten metal (usually iron) into a mould, this then left to cool and eventually solidify, after which the solid casting is removed from the mould, at which point the mould can be reused to make further copies of the item, should this be required.

In many respects, the process of foundry casting has remained unchanged since the Victorian Period, although there have been some advances in aspects such as safety.

The images above show a foundry scene from 1897 and a recent picture taken at our partner foundry as the metal was poured into the mould for the historic benches shown below following.

Although the focus of foundry casting is on the pouring of the metal, there are a number of stages that must be progressed through before this can take place.

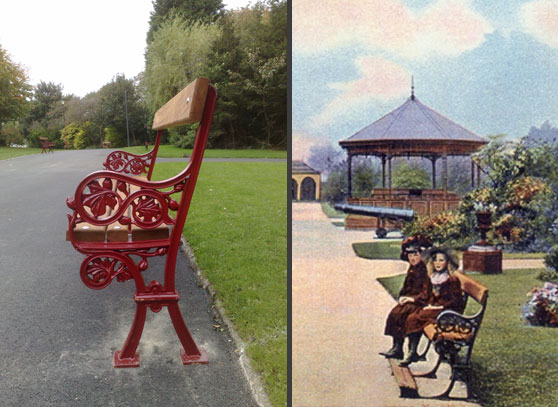

A high quality and detailed pattern carved and produced for producing replica castings of a Victorian ark Bench, the design of which was originally from the MacFarlane Foundry in Glasgow. These benches have been supplied for restoration projects at the Saltaire World Heritage Site and South Marine Park in South Shields.

Once the pattern has been produced and delivered to the foundry it is used to make a mould. This is generally achieved by pressing sand onto the pattern (ramming) in order to form an impression. In most cases the moulds will comprise of two halves, which are then placed together, with the resultant void being filled with metal during the pouring process. This type of mould making is called ‘cope and drag’.

In general, the finer the sand used for the mould, the more detailed the pattern and therefore the finer the casting produced, At our partner foundry we recognise the need for fine detail and crisply finished castings and therefore all moulds are produced using an appropriate fine grade of sand.

Having produced mould, a resin is applied to bond the sand, ensuring that the mould stays intact throughout the process, again leading to a high quality finish. Any excess resin is burnt off in order to prevent weakening of the mould.

Having produced the moulds, the iron is melted in the furnace and transferred to the ladle for pouring. The ladle is guided round the casting area by a team member and then held in position and tipped by the foundry team.

Once the metal has been allowed to cool and solidify, the two halves of the mould are separated and the casting is ‘broken out’. Although it is now recognisable as the required object, the casting is subject to two more processes before it is ready for use.

Firstly, the castings are shot blasted, bombarded with fine round particles of metal in order to produce a smooth finish and then taken for fettling, where tools such as grinders are used to remove any excess metal, leaving the finished casting ready for electroplating, priming and painting.

Once the layers of corrosion protection have been applied, followed by the decorative top coats of of paint, the castings are ready to be assembled into the final article.

The image above is newly produced bench having been installed on site and a historic postcard of the same location from the Lost Art Archive and which was used to help determine the choice of seats for the project.

Foundry casting is a skilled and deceptively complex process if the correct results are to be achieved. As we expect our castings to demonstrate good, crisp detail and be capable of lasting for at least as long as the items in our library of original Victorian castings, attention to detail is important at all stages of production and we are confident that our partner foundry achieves this at all times. In the past we have provided guided visits to the foundry for clients and representatives of funding bodies and all have been impressed with the attitude demonstrated towards the work and the quality of the castings produced.