The Ross Fountain, Edinburgh

In keeping with many structures of that age, it was no longer fully operational and in need of significant repairs, having suffered damage as a result of significant corrosion as well as vandalism and other accidental occurrences, including the removal of elements of the fountain, meaning that they were no longer present, requiring the production of replacement components.

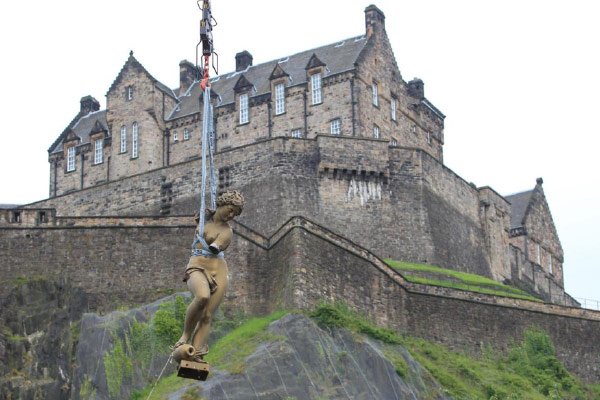

As with the Paisley fountain, the structure was completely disassembled, with the help of specialist crane contractors and transported back to the workshop, with the structure having been extensively photographed and recorded and each item tagged as it was removed to transportation.

Project Description

The Ross Fountain, Edinburgh

Princes Gardens, Edinburgh

Full restoration project, completed June 2018.

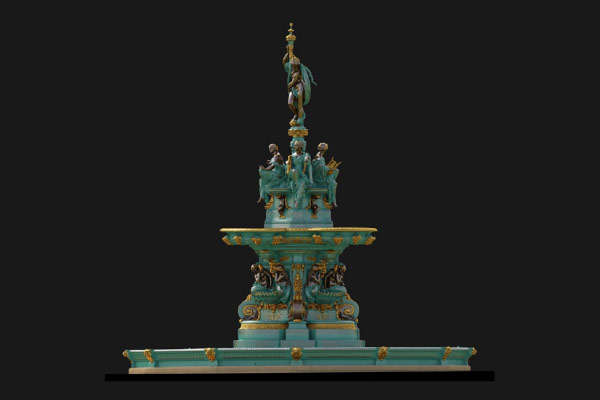

Situated at the heart of Edinburgh, in the shadow of the famous castle, The Ross Fountain is unusual in that, rather than having been produced by one of the great Scottish foundries of the day, it was produced at the Durenne Works in France and was a centrepiece of their exhibits at the Great Exhibition of 1862. Purchased as a philanthropic gesture by Daniel Ross, it was eventually installed its current position in 1872.

The magnificent structure is comprised of 122 individual components, including a number of greater than life size statues of the 4 muses of the age and a semi-naked female figure that adorns the top of the fountain and scandalised Victorian Edinburgh at the time. All this combines to produce a fountain that is over 40 feet high and over 100 tons in weight.

Once returned to the workshop, the condition of the items was recorded, photographed again and then cleaned to bare metal before being examined again and any further findings recorded. At this point, components were then dried out using a specialist technique devised by Lost Art in order to fully remove moisture from the components and to further facilitate the restoration process and to reduce the need for maintenance following reinstallation.

Much of the fountain was found to be in very poor condition and extensive repairs were carried out using brazing and welding techniques, with new sections of metal having to be used to replace sections broken or missing. In addition, missing components were replaced with new castings produced at the foundry using identical components from other parts of the fountain as a template. However, from looking at historical documents, it was also apparent that some unique components were absent, such as the easel and paintbrush held by the muse statue representing The Arts. In such cases our pattern maker would carve replacements in wood before using these to produce a pattern for the foundry to cast new components in iron (and in many cases spare items for storage in case of future loss).

Working with 150 year old cast iron structures that are damaged – often by fractures exacerbated by water ingress and subsequent frost heave – presents significant challenges for restoration workers but our staff were able to make use of techniques that they have developed through involvement in many comparable projects to ensure that the application of heat was carefully managed during the repair process.

In addition to repair of the decorative elements of the fountain, we also devised, produced and installed a new internal support structure that will ensure the longer term integrity of the fountain.

The fountain was then painted in a historically based colour scheme and subjected to a series of test assemblies of the sub sections of the fountain before it was returned to site by specialist haulier and reinstalled. At this point, the new plumbing and pumping system devised and installed by Lost Art could also be fine tuned to the returned structure.

Throughout the process the client (Ross Development Trust) was kept informed through a series of detailed reports that catalogued and documented progress, a procedure that we attempt to adhere to in all significant projects.

The project attracted both national and international interest from a variety of media.